Contact Phone

Electronic E-mail

News Center

Hangzhou Meiya provides you with perfect industrial fluid control products and application solutions

Characteristics and Principles of the Deaerator

Release time:

2021-01-26

Temperature and Pressure Reducing DeviceThe temperature and pressure reducing valve uses the opening of the opening and closing part in the valve body to adjust the flow rate of the medium, thereby reducing the pressure of the medium. At the same time, by adjusting the opening degree of the pressure regulating opening and closing component after the valve, the pressure after the valve is maintained within a certain range, and cooling water is sprayed into or after the valve body to reduce the temperature of the medium. This valve is called a temperature and pressure reducing valve.

The temperature and pressure reducing device is characterized by maintaining the outlet pressure and temperature within a certain range when the inlet pressure continuously changes. The pressure reducing valve is an important accessory of the pneumatic control valve. Its main function is to reduce the gas source pressure and stabilize it at a fixed value, so that the control valve can obtain stable gas source power for adjustment control. This valve should generally be installed horizontally in the pipeline. According to the structure, it can be divided into diaphragm type, spring diaphragm type, piston type, lever type and bellows type. According to the number of valve seats, manual single seat and double seat can be used. According to the position of the valve disc, it can be divided into positive action and reverse action.

Temperature and Pressure Reducing DeviceIn modern industry, it is used to reduce the parameters of superheated steam (high pressure pl, high temperature t1) emitted from different heat sources (such as power plants, industrial boilers or thermal power plants), and reduce temperature control. The steam through the equipment can accurately reach the steam parameters (pressure p2, temperature t2) required by the production process or users. It is widely used in thermal power generation, light industry (such as papermaking, printing and dyeing, food), petrochemical and other industries.

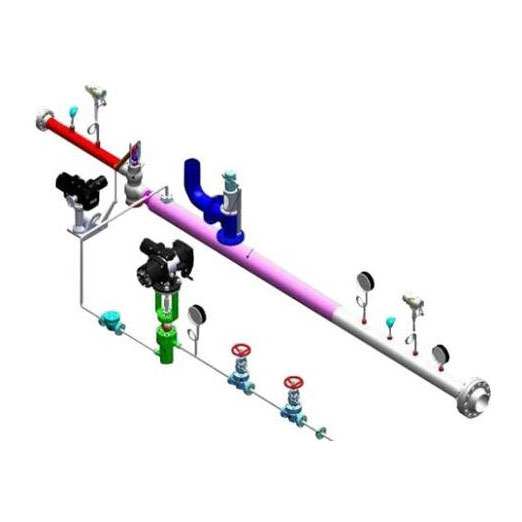

The temperature and pressure reducing device consists of four parts: pressure reducing system, temperature reducing system, safety protection device and automatic adjustment system. The pressure reducing system consists of pressure reducing valve 1 and orifice plate 2. The pressure reducing system consists of mixing pipe 3, nozzle 4, water distribution valve 5, and water supply throttling device. As shown in Figure 6, the shut-off valve 7 and the check valve safety protection device consist of the main safety valve 9, the pulse safety valve 10, the pressure gauge 11, the thermometer 12, and the steam pipe 13.

Previous article

Next article

Related News

2025-01-23

2025-01-23