Contact Phone

Electronic E-mail

Products

Products

Steam jet pump (pressure matcher)

Product Classification:

For more information, please contact us directly by phone or email

Number of views:

0

Product Description

Steam jet pump (pressure matcher)

Structural characteristics

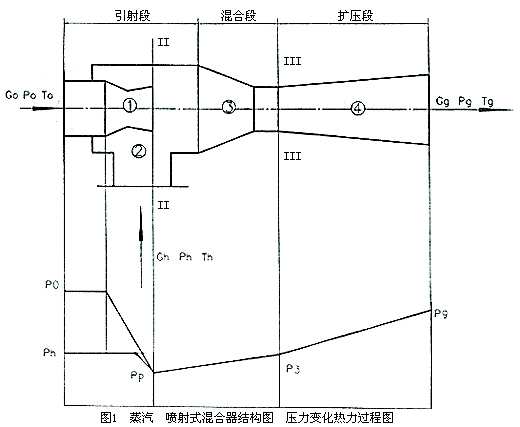

A vacuum obtaining device that uses fluid to transfer energy and mass. It uses water flow with a certain pressure, which is symmetrically distributed and sprayed out at a certain oblique angle through nozzles, converging at a focal point.

Because the jet water flow rate is particularly high, the pressure energy is converted into velocity energy, reducing the pressure in the suction area and generating a vacuum.

Several high-speed water flows will carry away the gas being sucked, and after fully mixing and compressing through the contraction section and throat diameter of the Venturi tube, molecular diffusion energy exchange and velocity equalization will occur.

After passing through the expansion section, the velocity decreases and the pressure increases, becoming greater than atmospheric pressure. It is then sprayed into the water storage tank (pool) from the outlet, and the non-condensable gas is separated. The water is recycled using a centrifugal pump to complete the suction process.

Using steam pressure matching to recover and utilize waste steam to create a vacuum

Thermal power industry

Improve the original design steam supply pressure of the thermal power plant to match the supply and use steam pressure.

Waste steam and waste heat returnRecovery

Recovery of discharged waste steam condensate and flash steam

Iron and steel industry

Steam pressure increase, energy-saving pressure reduction, condensate recovery

Various steam-using equipment in self-owned power plants, gas pressure increase and recovery, mixing of gases at different pressures

Other waste heat and waste gas recovery, etc.

Papermaking industry

Recovery of flash steam and condensate from the paper machine drying section

Pulp making process, complete set of equipment for waste steam recovery from steam cookers

Variable pressure steam supply for cooking steam

Light industry

Condensate and flash steam recovery

Self-owned thermal power plants or thermal power workshops

Typical cases

Nine Dragons Paper (Taicang) Co., Ltd. High temperature and high pressure steam pressure regulator post-reduction temperature regulator

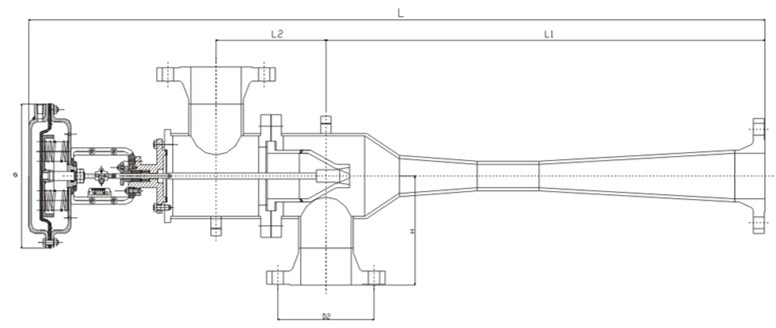

The pressure matcher uses a single-nozzle structure, and the shell is made of 12Cr1MoV forging.

Power steam: P1=8.83MPa T1=540°C Q1=8T/H

Steam to be sucked: P2=0.8~0.91MPa T2=220~240°C Q2=5T/H

Desuperheating water parameters: Pb=12~15Mpa Tb=158°C Qb=2T/H

Outlet steam: P3=1.8Mpa T3=240°C Q3=15T/H

This project was put into operation in June 2012 and has been operating stably with good economic benefits.

Customer Message

If you have any questions, please fill out the form and we will contact you as soon as possible