PC头部-联系电话、邮箱

手机-头部WhatsApp代码

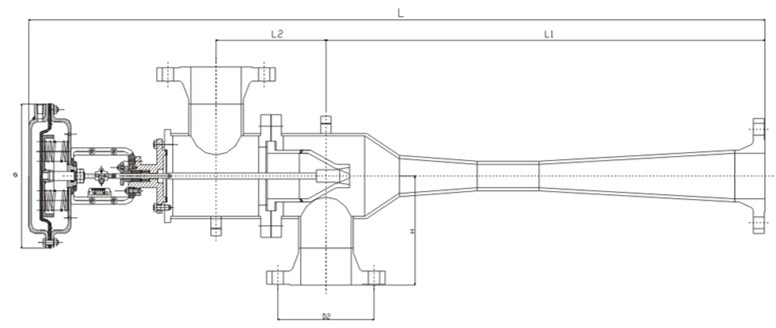

Steam jet pump (pressure matcher)

Steam jet pump (pressure matcher)

Structural Feature

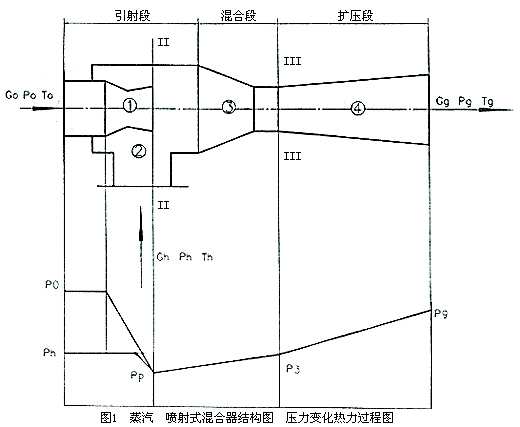

A vacuum acquisition device that uses fluid to transfer energy and mass, and uses a certain pressure of water flow to spray out through nozzles symmetrically and evenly distributed with a certain side slope, and aggregate in a focal point

Due to the extremely high flow rate of the jet water, the pressure energy is converted into velocity energy, and the pressure in the suction zone is reduced to produce vacuum

Several high-speed water streams will grab the sucked gas, pass through the contraction section of the venturi tube and fully mix and compress with the throat diameter, perform molecular diffusion energy exchange, and the speed is balanced

When the speed decreases through the expansion section, the pressure increases, and the pressure is greater than atmospheric pressure and sprayed into the storage tank (pool) from the outlet, and non-condensable gas is precipitated. The water is recycled by the centrifugal pump to complete the suction process

Application of steam pressure to match exhaust steam recovery and utilization to suction vacuum

Thermoelectric industry

Increase the steam supply pressure of the original design of the thermal power plant to match the steam supply and consumption pressures

Exhaust steam and waste heat recovery

Recovery of exhausted steam condensate and flash steam recovery

steel industry

Steam pressure increase, energy saving and pressure reduction, condensate recovery

Various steam equipment for self-provided power plants, gas pressure recovery, gas mixture of different pressures

Other waste heat and gas recovery, etc.

Paper industry

Recovery of flash steam and condensate in the dryer section of a paper machine

Pulping process, complete set of steam recovery equipment

Variable pressure steam supply for cooking steam

Light industry

Condensate and flash steam recovery

Self-provided thermal power plant or thermal power workshop

Typical Case

Nine Dragons Paper (Taicang) Co., Ltd. high temperature and high pressure steam pressure distributor rear desuperheater

The pressure matcher adopts a single nozzle structure, and the shell adopts 12Cr1MoV forgings

Power steam is P1=8.83MPa T1=540°C Q1=8T/H

The absorbed steam is P2=0.8~0.91MPa T2=220~240°C Q2=5T/H

Decreasing temperature water parameter Pb=12~15Mpa Tb=158°C Qb=2T/H

The outlet steam is P3=1.8Mpa T3=240°C Q3=15T/H

The project was put into use in June 2012, with stable operation and good economic benefits

Customer Message

How to contact us?

底部-联系我们

Hangzhou Meiya Generation Equipment Co., Ltd.

E-mail: hzmysales@chinamy-power.com

Company address: Room 1605, laiyinda building, 535 Wensan Road, Hangzhou, Zhejiang, China

Chinese

Chinese